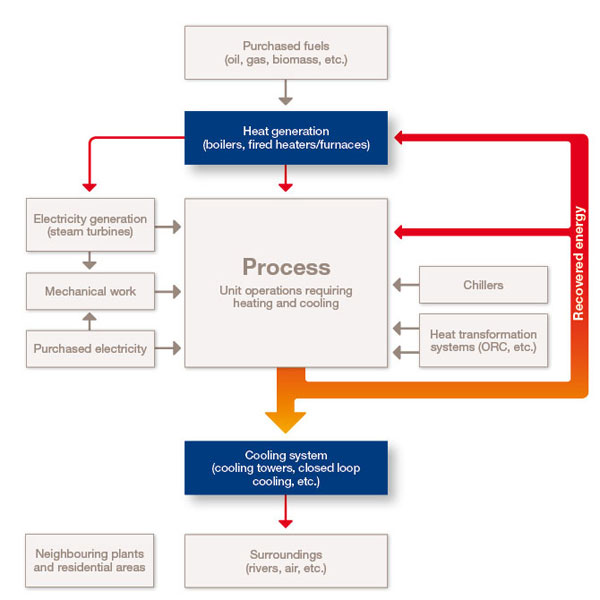

Considering heat recovery can lead to substantial savings in both new and existing plants when planning new utility investments. It can cut both future operating costs, utility systems and capital investment costs.

Recovering process heat reduces investment costs in systems for heat generation and cooling, as well as costs for space.

Recovering heat leads to a lower need for new heat, reducing the capacity need of boilers, direct fired heaters and furnaces.

The first thing to consider when planning new cooling capacity is how to reduce the input of heat into the system. Recovering heat reduces the cooling need and a cooling tower of less capacity will suffice.

10 MW of recovered heat can lead to 500,000 EUR reduced steam boiler cost, assuming:

Waste heat recovery often reduces the load on the utility systems.